In this article, we’d like to share a few of the lessons we’ve learned in our practice so that you can embark on your intelligent automation journey a step ahead of the rest.

As Henry Ford once said, “The only real mistake is the one from which we learn nothing.” At Synpulse, we’ve taken these words to heart. For every project, we do a lesson learned exercise to improve our delivery quality and enrich our client’s preparations for future engagements.

What can possibly go wrong? Potential pitfalls

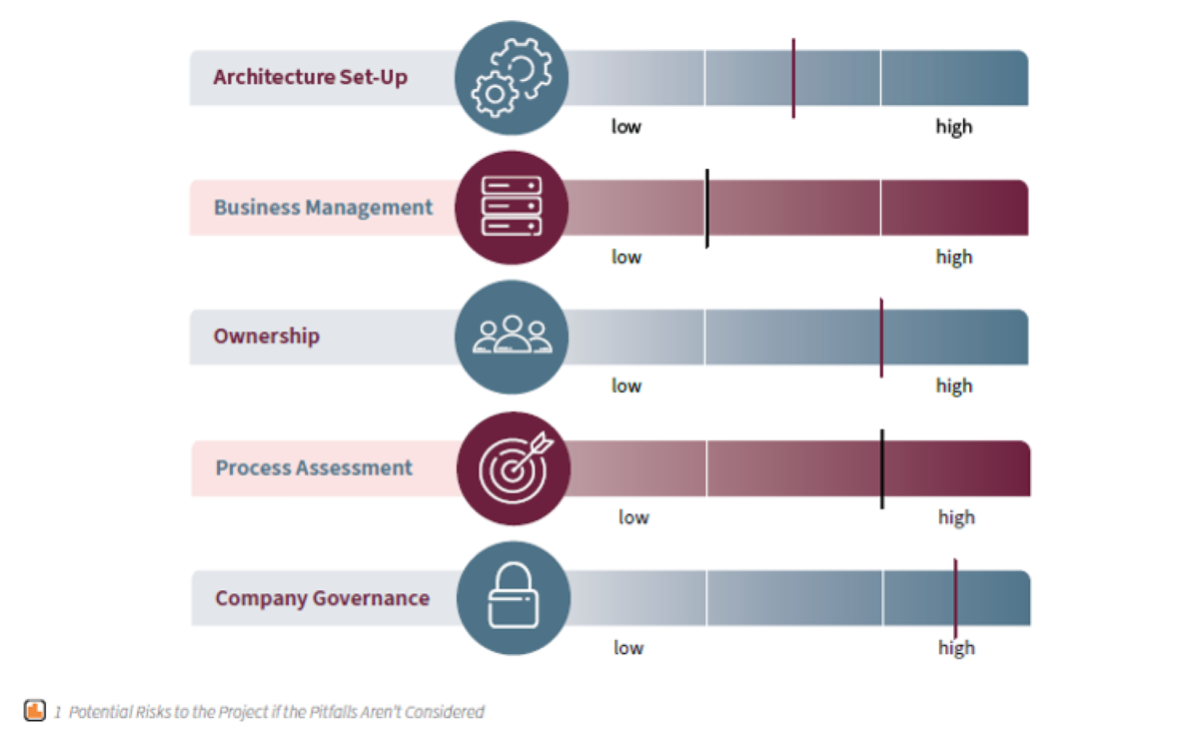

No project runs faultlessly, and you’ll always encounter some unforeseen pitfalls. Here are some of the most common dangers and how to avoid them (see Figure 1):

- Architecture setup. When a project starts, we want to hit the ground running and start configuring the lowest level of the development as soon as possible. The recommended setup is for the automation software to sit on a virtual machine (VM) and for both the production and live environments to be split across different VMs. As many as six VMs may be needed for a smooth configuration period. One of the main issues we encounter is that the system architecture isn’t ready for development when we start. This can result in long wait times.

- Business management. There’s no hard and fast rule as to where robotic process automation (RPA) should sit within the business structure. It depends entirely on how you want it to be managed. You may have a huge internal automation structure, in which case RPA should have its own dedicated department. Alternatively, automation may be unique to a specific division, meaning it would make more sense for it to be managed internally by that department. Wherever you locate your RPA, you have to consider scalability.

- Ownership. Once development is finished, you have to maintain your robot. We design our solutions to be durable and able to recover from the most unexpected outcomes. But updates to internal and external systems may mean that elements need to be re-spied. Another pitfall is that issues with the environment will likely cause the robot to encounter unexpected paths, and an owner will be needed on hand to manage this. Even if these fixes are minor and uncomplicated, dedicated personnel are needed to deal with them. You also need to make sure that output from the process in the form of termination and exception reports is handled accordingly.

- Process assessment. A common pitfall we encounter is a lack of a proper process assessment phase. Determining whether a specific process lends itself to automation or not is one of the first steps, and consequently one of the most important for an effective outcome. Processes that are not suited to automation lead to unexpected outcomes and ROIs, and if this is not established until the development is well under way, it can greatly increase risks to the project.

- Company governance. A robot works by mimicking the actions performed by a user – be it a read, a write, or a click. For this to function flawlessly, the environment interacted with must not time out or lock while the robot is in use. One of the most common and condemning pitfalls we encounter is a VM that’s not accessible when the robot requires it. Similar to a human, the robot is unable to access anything on the machine while it’s locked. For the robot to work successfully, it must have access to the virtual machine screen.

Are our expectations realistic? Some common misconceptions

As the buzz surrounding RPA has grown, so have the misconceptions! We explored some false expectations around RPA that should be front of mind.

Click below to download those misconceptions and our take on it.

Keep your eyes open!

As we opened with a quote, it seems only right that we close with one. The astute CTO of AWS, Werner Vogel, once said, “Everything fails all of the time, so plan for failure and nothing fails.” Our key takeaway for new entrants into the automation space is to step boldly into it with your eyes wide open. If you consider every eventuality before taking the plunge, and heed our lessons learned as you plan implementation, you’ll soon have your robots working diligently and intelligently for you and your business.